L&T Group Websites

- Corporate

- Corporate – Arabic

- CarbonLite Solutions

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Precision Engineering and Systems

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

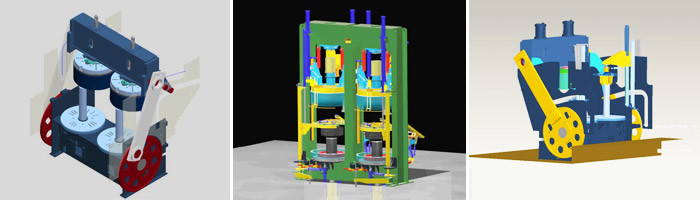

Manufacturing Facilities

Our manufacturing facility in Kancheepuram is equipped with state-of-the-art technology and fabrication facilities to manufacture heavy machines. Backed by continuous innovation and R&D, we supply machines to tyre majors around the world.

DESIGN ENGINEERING AND R&D

L&T Rubber Processing Machinery has a team of highly qualified engineers with experience in designing complex mechanical, hydraulic, electronic and electrical systems. Rubber Processing Machinery has in-house facilities for designing mechanical, hydraulic, electronic and electrical systems.

Rubber Processing Machinery has close interaction with reputed educational institutions such as Indian Institute of Technology, Chennai, and Anna University for design and validation of complex systems used in Rubber Processing Machinery.

FABRICATION

Our fabrication facilities include:

- CNC Profile Burning machine: (Max. 300 mm thick plate)

- Plate straightening machine: (Max. 300 mm thick plate)

- Welding Systems: MMA, MIG, TIG & Pulsed TIG / Shot Blast Booth (4m x 4m x 3m) / Stress Relieving Furnace

- Welding Processes for: Carbon steels, Stainless Steels, Aluminum & Pure Nickel

- Welders: Qualified by reputed external agencies

MACHINING & METROLOGY

We are equipped with state-of-the-art high precision, Multi Axis CNC Boring Machines and Vertical Turret Lathes to cater to all our manufacturing requirements.

There are over 15 machines and Machining Centres offering highly accurate machining.

The Metrology section is equipped with the following facilities:

- Universal Testing Machine

- Strain Gauging Instruments

- Precision Master Gauges

- Range of Internal and External Micrometers to read upto 2000 mm

- Ultrasonic flaw detectors, Hydraulic test stations

ASSEMBLY

With over 200 trained and qualified workmen specialising in Assembly activities and with a total Assembly Area of over 9000 Sq km, L&T RPM has one of the most advanced Assembly shops in the region, with dedicated space for various machine sizes.

- Capable of handling big presses

- Simultaneous assembly of several presses

- Assembly capacity of over 400 presses per year

IT INFRASTRUCTURE

L&T RPM has a well-established Information Systems Department (ISD), with the objective of strategizing, evolving and implementing IT solutions, infrastructure and applications with relevant emerging technologies.

We have implemented Enterprise Software - JD Edwards - ERP for Business transactions linking every sequence of customer order execution, and we use Wrench Enterprise application for Product Data Management (PDM).

L&T RPM has also developed Operational Dashboards and provides MIS through Intranet / Crystal Reports.

Our IT-Infrastructure facility includes:

- State-of-the-art Server Room

- High End Servers and Storage for ERP

- VMware Virtualised Servers with Failover Architecture

- LAN with Optical Fiber Network

- 24 x 7 - 4 MBPS Internet connection

- 34 MBPS link between KPM & MPM

- Mailing through 10 MBPS-MPLS link