L&T Group Websites

- Corporate

- Corporate – Arabic

- CarbonLite Solutions

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Precision Engineering and Systems

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

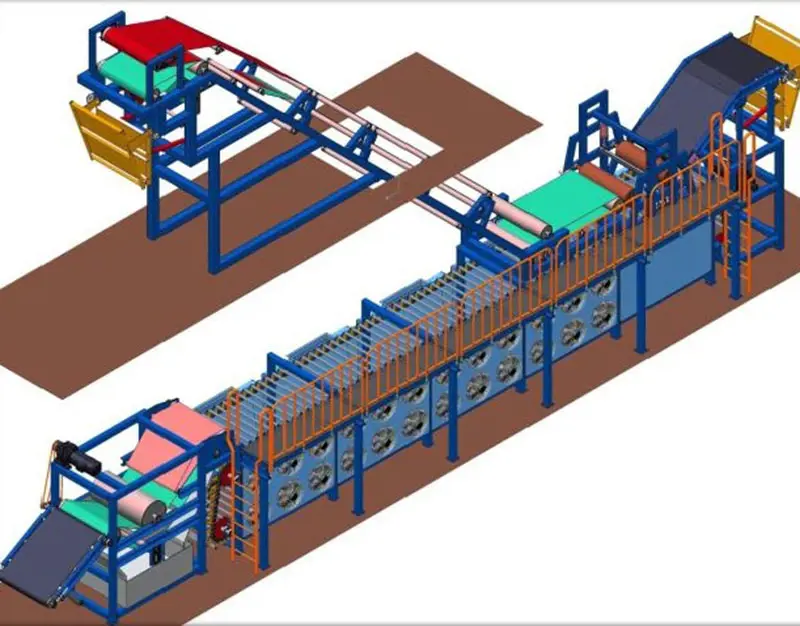

Batch-Off Units

All Products- Pictures

The Batch-off unit with wig-wag stackers consists of the following main components.

- Take-off conveyor section which includes the driven take-off conveyor belt.

- Dip tank for cooling and for applying the anti-tack medium, complete with drive unit.

- Cooling festoon rack, provided with a chain conveyor with fixed suspension bars with a number of cooling ventilators, drive and a platform.

- Wig-wag stacking units for discharging the rubber as an endless strip, complete with the drive unit.

- The complete electrical and pneumatic equipment with switch board, operating mechanism and connection boxes, safety devices, etc.

- This being a custom built equipment, the customer has to provide details of his requirement. A typical specification of the batch off unit is given below and the customer can provide the details of his requirement.

PRODUCT INFORMATION

|

Number of sections in cooling rack |

1.5 m x 14 |

|

Maximum width of the machine |

2700 mm |

|

Maximum height of the machine |

10600 mm |

|

Number of cooling fans |

19 |

|

Distance between carrier bars |

6" |

|

Temperature of stock at entrance |

150 deg.C |

|

Slab width |

600 - 900 mm |

|

Slab thickness max./min |

12 mm/8 mm |

|

Maximum loop length in cooling rack |

1500 mm |

|

Capacity in kg/hour (sg = 1.2) |

8000 |

|

Capacity dip tank |

1275 ltr |

|

Discharge speed from mill |

7-42 m/min |

|

Air output of cooling ventilators |

8500 m3/hr |

|

Capacity circulation pump of dip tank |

200 ltr/min. |

|

Operating pressure of equipment |

6 bar |

|

Power of dip tank motor |

5.5 kW |

|

Power of circulation pump |

0.68 kW |

|

Power of cooling rack motor |

4kW;2160rpm DC |

|

Power of fan motors |

0.75 kW |

|

Power of Wig-wag motor Bottom |

2.25 kW |

|

Top |

4 kW |

|

Discharge speed wig-wag unit |

7 - 42 m/min |